Our commitment to quality is ingrained in our company’s culture. Golis Machine is constantly improving through the continuous education of our employees and adoption of state-of-the-art technologies to improve our processes and achieve total customer satisfaction.

Throughout the manufacturing process, our Quality Systems implements various tools:

Golis Machine will also provide all necessary post–production documentation:

To ensure consistency in our process, we conduct the following:

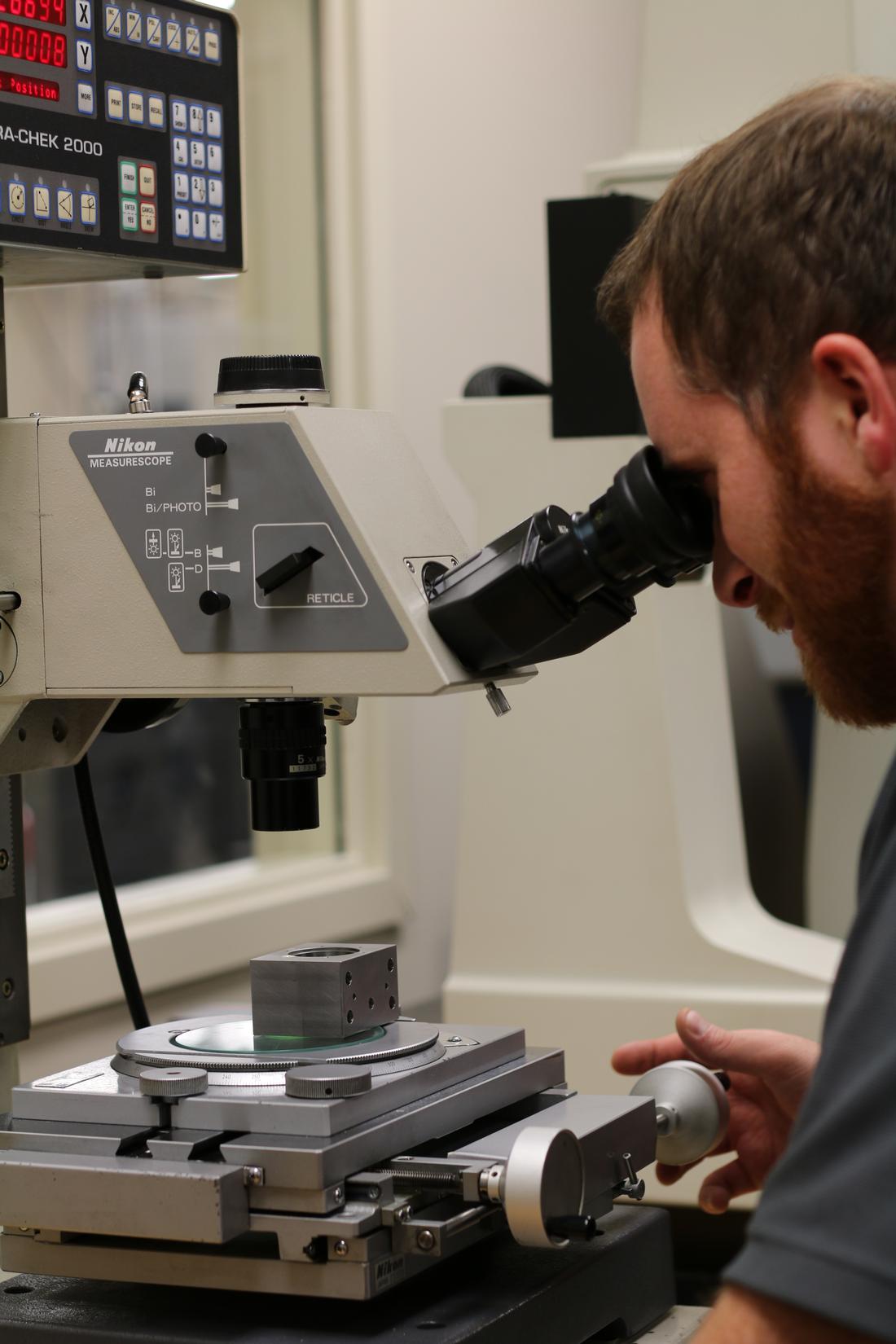

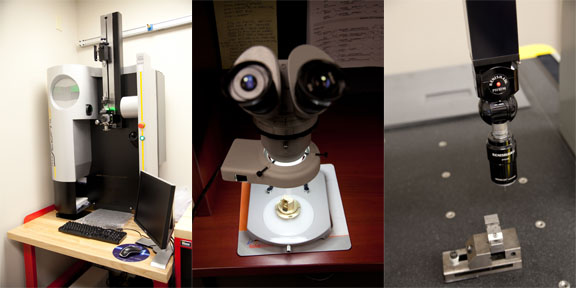

Golis Machine utilizes CAD capability through the use of SolidWorks. We maintain and use various types and styles of inspection equipment, all calibrated in house or by the manufacturer. In addition to an array of handheld gages, we have on hand:

All of our Automated Measuring Systems have SPC capabilities (Statistical Process Control) which gives Golis Machine the ability to provide process capability data and allows us to match or exceed OEM capabilities. Golis Machine believes in providing our customers with an exceptional level of quality in our products. Over the past 35+ years we have created a program to support this belief, in a clean, modern facility, designed specifically for the production of high precision parts. Our Quality System, along with our great team of dedicated employees, have met and gone beyond the guidelines that certify us to AS9100 Certified.

GOLIS MACHINE, INC.

92 Industrial Drive, Montrose, PA 18801

Phone: 570-278-1963

Fax: 570-278-2773

©2022 Golis Machine, Inc. Privacy Policy

agen slot online | slot online pulsa | judi slot online | slot online terbaik | daftar slot online | slot online terbaik | slot online resmi | login sbobet | sbobet wap | judi bola online | joker123 apk | situs joker123 | casino online terpercaya | casino online terbaik | login sbobet | slot online | agen sbobet resmi | judi slot | live slot | togel online terpercaya | Idn Poker online | joker123 | sbobet | situs judi slot | agen slot online | slot online terlengkap | slot online terpercaya | slot online terbaik | sbobet resmi | daftar joker123 | agen sbobet resmi | poker online resmi | idn poker terpercaya | situs sbobet terpercaya | agen slot online | agen sbobet | sbobet | slot online |

idn poker | joker123 | slot online | togel online | sbobet mobile | poker online terpercaya | slot online